Continuous Flow Plunger Lift Upstroke

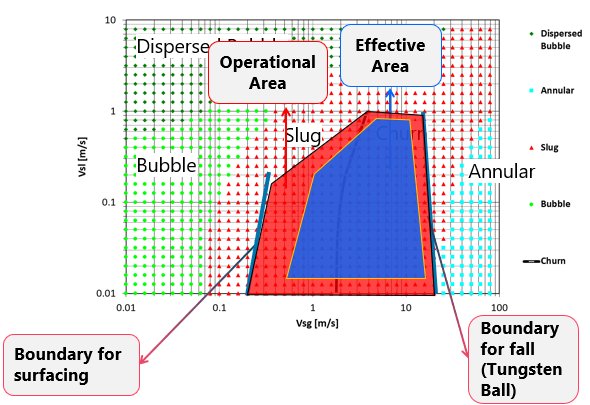

Understanding the mechanics of the continuous flow plunger (CFP) lift upstroke stage is important to

- Develop an operational envelope for CFP lift and PAGL at the design stage.

- Plunger selection

- Shut-in/after-flow time settings

- Gas injection optimization